Analysis of heat insulation strips for aluminum alloy doors and windows

- Categories:新闻中心

- Author:

- Origin:

- Time of issue:2017-06-09 00:00

- Views:

(Summary description)

Analysis of heat insulation strips for aluminum alloy doors and windows

(Summary description)

- Categories:新闻中心

- Author:

- Origin:

- Time of issue:2017-06-09 00:00

- Views:

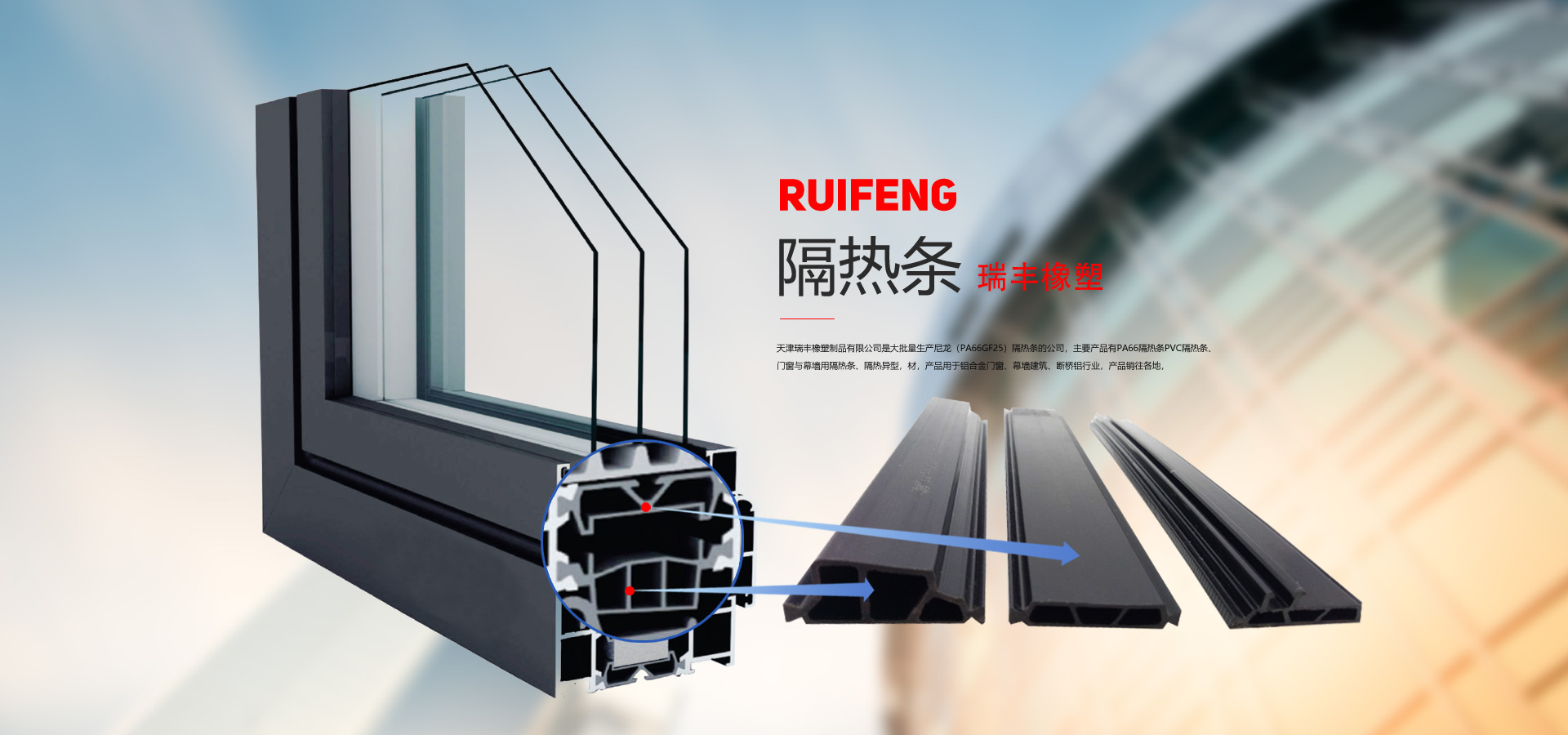

As a key component of insulated aluminum alloy doors and windows and curtain walls, heat insulation strips have created a new product field with the application of insulated aluminum alloy doors and windows and curtain walls. Simply put, the heat-insulating aluminum profile is to divide the original one-piece profile into two on the basis of the traditional aluminum profile, and then the two separate parts are connected together by means of mechanical compounding by two heat-insulating strips. The nature of the heat insulation strip determines that it must have high strength and low conductivity at the same time, otherwise it will cause major quality hazards in the insulated aluminum alloy doors and windows and curtain walls (insufficient strength will cause the insulation aluminum profile to escape from the insulation strip The connection is broken), or it loses the meaning of heat insulation (the heat insulation effect cannot be guaranteed if the conductivity is high). Therefore, the performance of the heat insulation strip must be strictly investigated:

One, appearance

The heat insulation strip should be smooth and flat as a whole, without shrinkage, porosity, scratches and mold extrusion traces, and the unique luster of minerals (glass fiber distribution) can be seen on the light, and there should be no parting line marks on the end of the heat insulation strip. .

2. Overall dimensional accuracy

The size deviation of different parts of different batches or the same heat insulation strip is less than 0.1mm, and the parallelism is standard, otherwise the stability of the composite strip cannot be guaranteed, and the internal distortion stress is easily caused, which makes the insulation profile The processed heat-insulated doors and windows have hidden quality risks that are easily deformed.

Three, material properties

1, load deformation temperature

The temperature at which the sample undergoes thermal deformation to a certain index under a certain load is called the load deformation temperature. Different heat insulation strips may have a large difference in load deformation temperature. This performance directly reflects the heat resistance of the heat insulation strip.

2, thermal conductivity

The metal material (such as aluminum alloy, stainless steel, etc.) as the window frame has a large thermal conductivity, which makes the heat exchange between the inside and outside the house very fast, which is not conducive to the heat insulation of the house in summer, and it is also not conducive to the house in winter. Heat preservation and energy saving. Thermal conductivity is a manifestation of the thermal insulation ability of the heat insulation strip material. The higher the thermal conductivity, the worse the thermal insulation ability of the insulation strip; on the contrary, the better the thermal insulation ability.

3, linear expansion coefficient

Insulation strips are used as connectors for aluminum alloy doors, windows, and curtain wall thermal insulation and energy-saving broken bridge aluminum. The expansion coefficient of the material must be close to that of aluminum to prevent the insulation strips from falling off from the metal due to thermal expansion and contraction.

Four, product mechanical properties

1, transverse tensile strength

When used in winter and summer, there is a big temperature difference between the inner and outer cavity of the heat insulating profile that composes the heat insulating aluminum window. This temperature difference will cause different deformation trends between the inner and outer cavity aluminum materials. In summer, the temperature of the outer cavity profile is high, causing the outer arch to shrink inward. In winter, the temperature of the outer cavity profile is low, causing the inner arch to shrink outward. This constant arching stress will cause the heat-insulating profile to produce a large transverse tension in the middle. If the transverse tensile strength of the insulation strip is low, it will break, resulting in quality problems of the insulation profile.

2, longitudinal tensile strength and elastic modulus

The longitudinal tensile strength reflects the mechanical properties of the heat insulation strip in the longitudinal direction. At the same time, the elastic modulus is one of the indexes that can most characterize the performance of the material. In engineering, the elastic modulus is called the stiffness of the material. The resistance to elastic deformation, the larger the value, the smaller the elastic deformation under the same stress, and the more rigid the material.

3, impact strength

When the product is subjected to dynamic load, the impact strength (toughness) performance index of the material is required. The level of impact strength also indicates the toughness performance of the material, which is one of the performance indicators for material selection. Good toughness can ensure that the heat insulation strip has a comparison during assembly. High yield.

Copyright © 2020 tjruifeng.com.cn All rights reserved 津ICP备11000889号 Manage Powered by www.300.cn

The official WeChat