Product Description

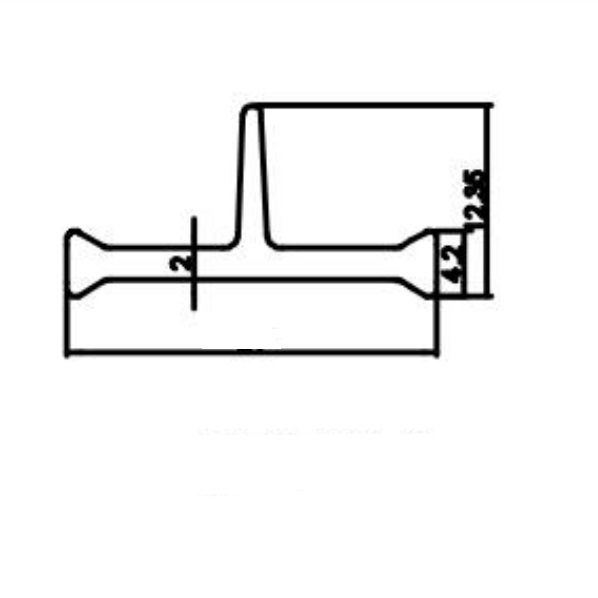

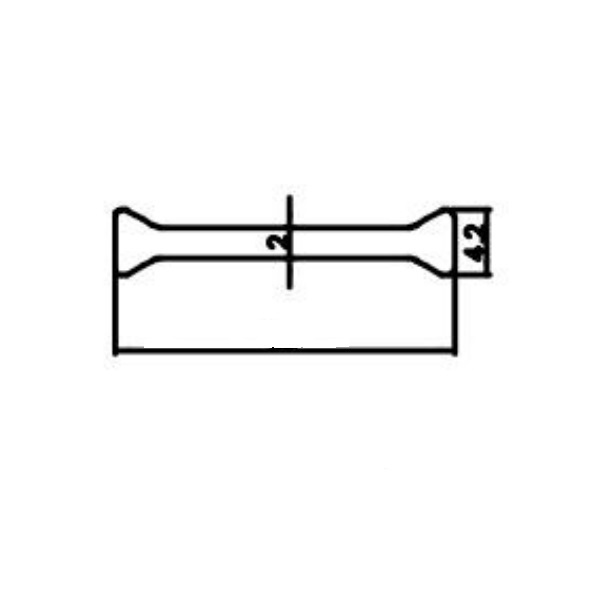

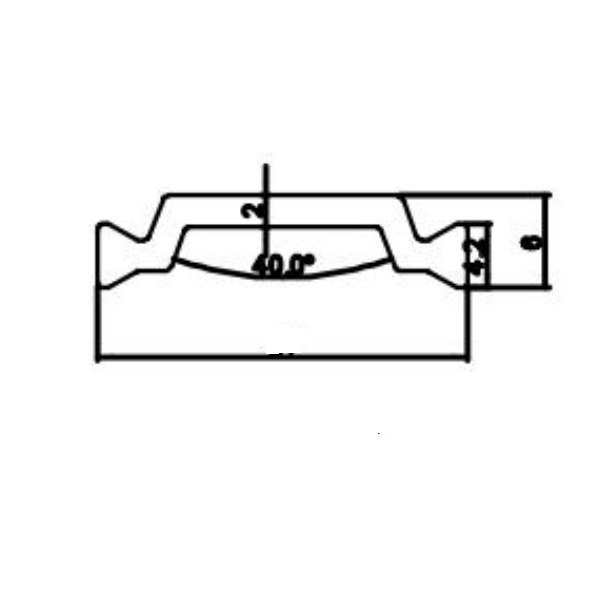

Thermal Break Model:

12mm, 14.8mm, 18.6mm, 20mm, 22mm, 24mm

Thermal Break Advantages:

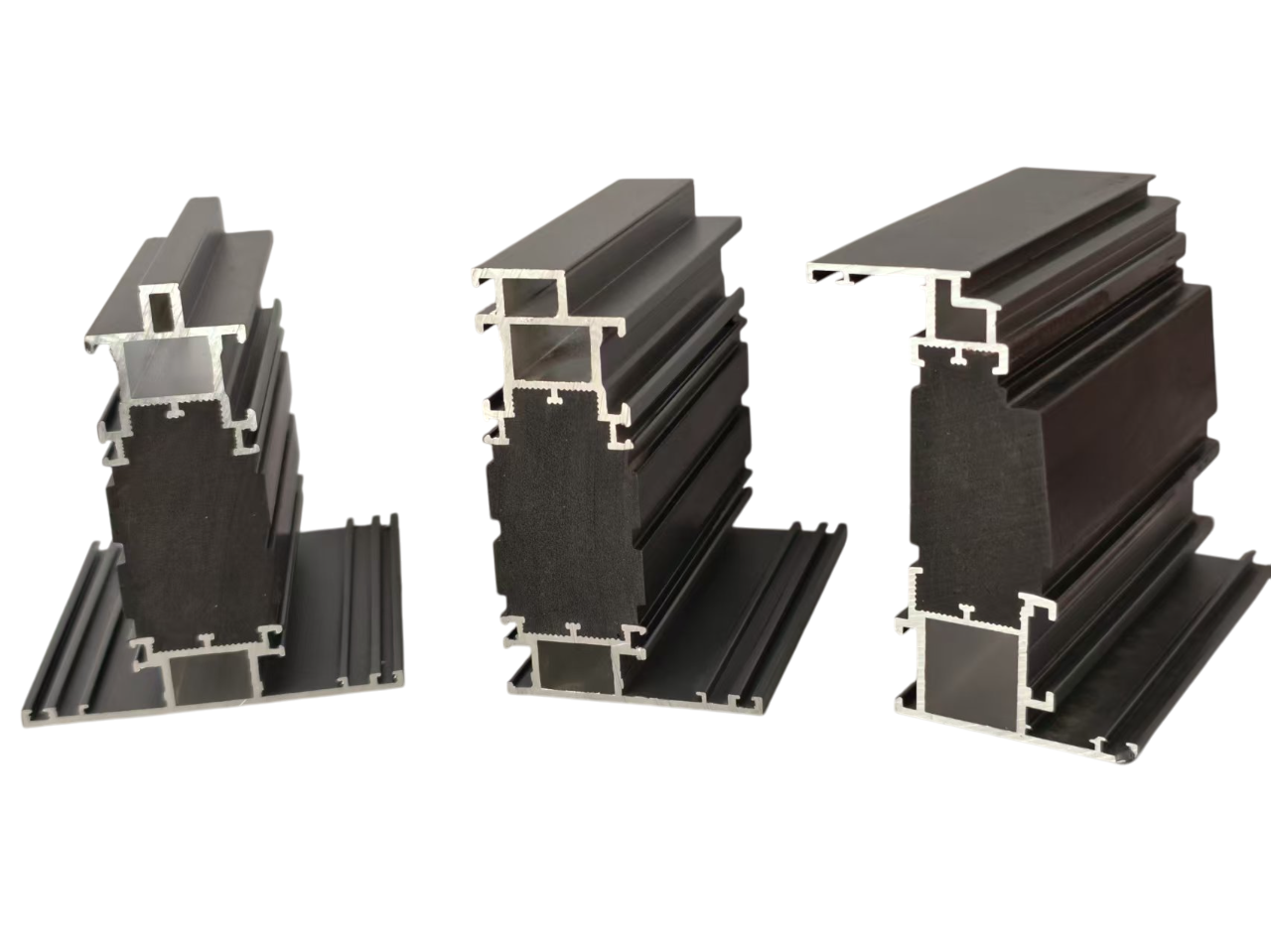

Tianjin Ruifeng thermal break is composed of 65% nylon (PA66) and 25% glass fiber (GF), black in color. As the main heat insulation component, it is suitable for aluminum alloy doors and windows, framed curtain walls, and plays a decisive role in the wind pressure resistance, water tightness, and air tightness of doors and windows.

Product Advantages:

1. Using cold extrusion technology, glass fibers are uniformly distributed in multiple directions, resulting in high strength to meet design needs and ensure the stability of insulated aluminum alloy doors and windows and framed curtain walls.

2. The coefficient of linear expansion is close to that of aluminum profiles, ensuring that the thermal break and aluminum material remain tightly bonded under prolonged sun exposure and severe cold, without displacement or detachment.

3. Processing temperature up to 220 degrees, fully meeting the process requirements of pre-insertion and post-spraying.

4. Dimensional accuracy is less than 0.05mm. High dimensional accuracy facilitates the serration rolling process and ensures the airtightness, water tightness, and wind pressure resistance of doors and windows and curtain walls.

5. Excellent machinability, allowing for the secure fastening of hardware.

6. Features fire resistance, high temperature resistance, chemical corrosion resistance, anti-aging, anti-UV, and other functions. It is more environmentally friendly and energy-efficient, has a longer service life, and is also recyclable.

7. Unique formula and special heat stabilizers ensure the excellent quality of the thermal break.

Product Performance:

● Enhanced Comfort: Heat exchange between the human body and the environment depends on the temperature, flow rate of indoor air, and the outdoor air temperature. Therefore, by using insulated profiles, the temperature of the door and window surfaces is adjusted to not be lower than 12-13℃ to achieve the most comfortable environment for the human body.

● Environmental Protection: The use of insulation systems reduces energy consumption, air conditioner use, and environmental pollution.

● Condensation Prevention: Appropriate system design makes the inner surface temperature of the insulated profiles close to the indoor temperature, greatly reducing the possibility of excessive indoor moisture condensing on the inner surface of the profiles.

● Energy Saving

--Reduces heat loss outdoors in winter, lowering heating energy consumption;

--Reduces heat transfer indoors in summer, lowering cooling energy consumption;

● Sound Insulation: Appropriately reduces noise pollution.

Instructions for Use:

Thermal breaks made of polyamide have a certain water absorption rate, the speed and amount of water absorption depend on the following factors:

● Ambient Temperature

● Ambient Humidity

● Storage Conditions

In summer, the temperature and humidity in the warehouse are relatively high, and the amount of water absorbed by the thermal break will be more than in other seasons, so it should be stored for a short period. Therefore, we recommend storing the thermal break indoors at a temperature of 15-20 degrees. When a single bundle of thermal breaks is moved from the shelf, it may twist and deform. If it is not straightened in time, permanent twisting and deformation will occur. Therefore, we recommend minimizing the bending degree of the thermal break during storage. To prevent twisting and bending deformation, please minimize the storage time before processing. If you have any specific questions, please contact us, and we are happy to provide you with relevant services.

T-type-1

We have a professional export team and our brushes are exported to European and American countries. We can do OEM and ODM services. We have a brush design team that develops and designs new brushes every year.

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Product Description

Thermal Break Model:

12mm, 14.8mm, 18.6mm, 20mm, 22mm, 24mm

Thermal Break Advantages:

Tianjin Ruifeng thermal break is composed of 65% nylon (PA66) and 25% glass fiber (GF), black in color. As the main heat insulation component, it is suitable for aluminum alloy doors and windows, framed curtain walls, and plays a decisive role in the wind pressure resistance, water tightness, and air tightness of doors and windows.

Product Advantages:

1. Using cold extrusion technology, glass fibers are uniformly distributed in multiple directions, resulting in high strength to meet design needs and ensure the stability of insulated aluminum alloy doors and windows and framed curtain walls.

2. The coefficient of linear expansion is close to that of aluminum profiles, ensuring that the thermal break and aluminum material remain tightly bonded under prolonged sun exposure and severe cold, without displacement or detachment.

3. Processing temperature up to 220 degrees, fully meeting the process requirements of pre-insertion and post-spraying.

4. Dimensional accuracy is less than 0.05mm. High dimensional accuracy facilitates the serration rolling process and ensures the airtightness, water tightness, and wind pressure resistance of doors and windows and curtain walls.

5. Excellent machinability, allowing for the secure fastening of hardware.

6. Features fire resistance, high temperature resistance, chemical corrosion resistance, anti-aging, anti-UV, and other functions. It is more environmentally friendly and energy-efficient, has a longer service life, and is also recyclable.

7. Unique formula and special heat stabilizers ensure the excellent quality of the thermal break.

Product Performance:

● Enhanced Comfort: Heat exchange between the human body and the environment depends on the temperature, flow rate of indoor air, and the outdoor air temperature. Therefore, by using insulated profiles, the temperature of the door and window surfaces is adjusted to not be lower than 12-13℃ to achieve the most comfortable environment for the human body.

● Environmental Protection: The use of insulation systems reduces energy consumption, air conditioner use, and environmental pollution.

● Condensation Prevention: Appropriate system design makes the inner surface temperature of the insulated profiles close to the indoor temperature, greatly reducing the possibility of excessive indoor moisture condensing on the inner surface of the profiles.

● Energy Saving

--Reduces heat loss outdoors in winter, lowering heating energy consumption;

--Reduces heat transfer indoors in summer, lowering cooling energy consumption;

● Sound Insulation: Appropriately reduces noise pollution.

Instructions for Use:

Thermal breaks made of polyamide have a certain water absorption rate, the speed and amount of water absorption depend on the following factors:

● Ambient Temperature

● Ambient Humidity

● Storage Conditions

In summer, the temperature and humidity in the warehouse are relatively high, and the amount of water absorbed by the thermal break will be more than in other seasons, so it should be stored for a short period. Therefore, we recommend storing the thermal break indoors at a temperature of 15-20 degrees. When a single bundle of thermal breaks is moved from the shelf, it may twist and deform. If it is not straightened in time, permanent twisting and deformation will occur. Therefore, we recommend minimizing the bending degree of the thermal break during storage. To prevent twisting and bending deformation, please minimize the storage time before processing. If you have any specific questions, please contact us, and we are happy to provide you with relevant services.

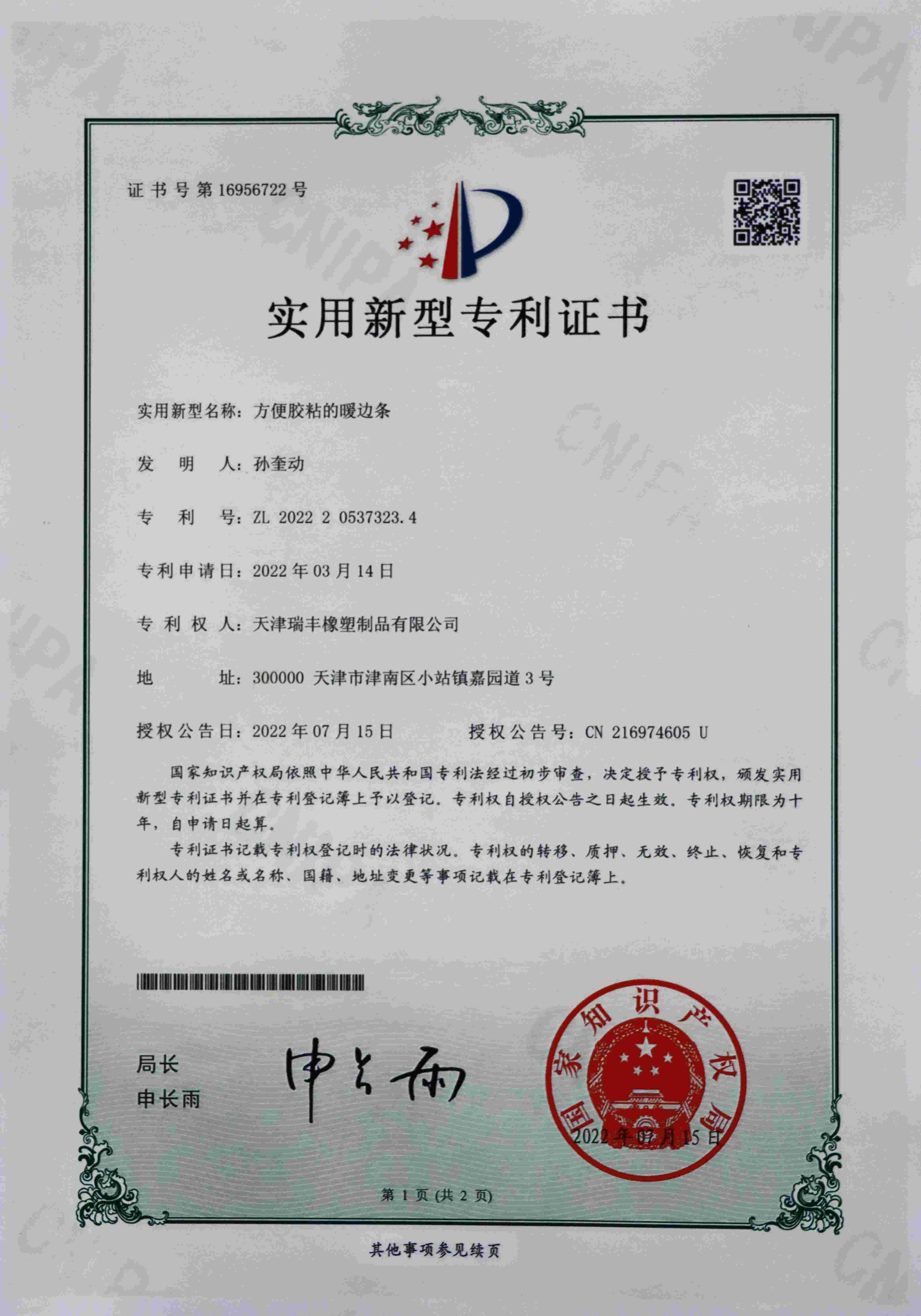

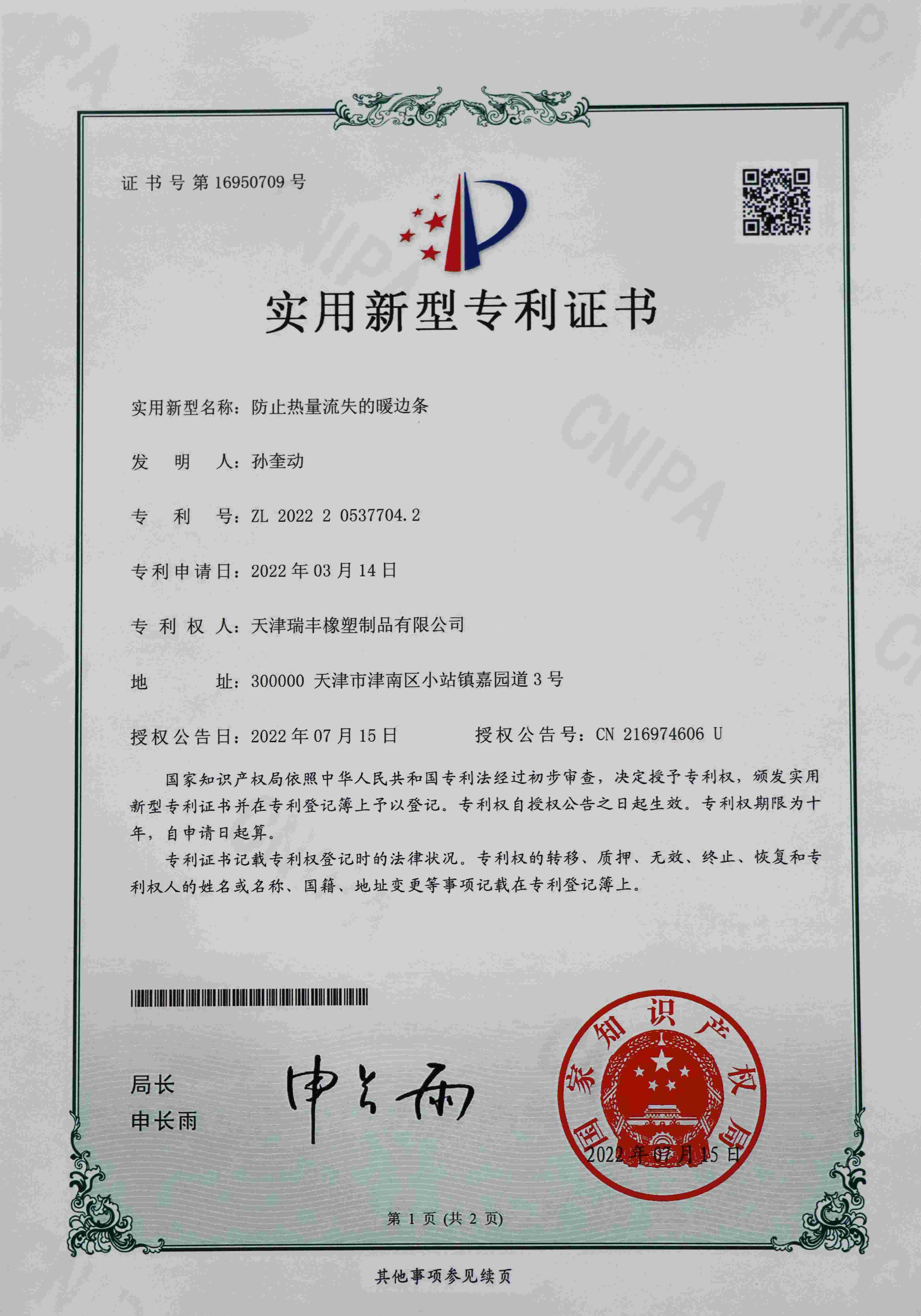

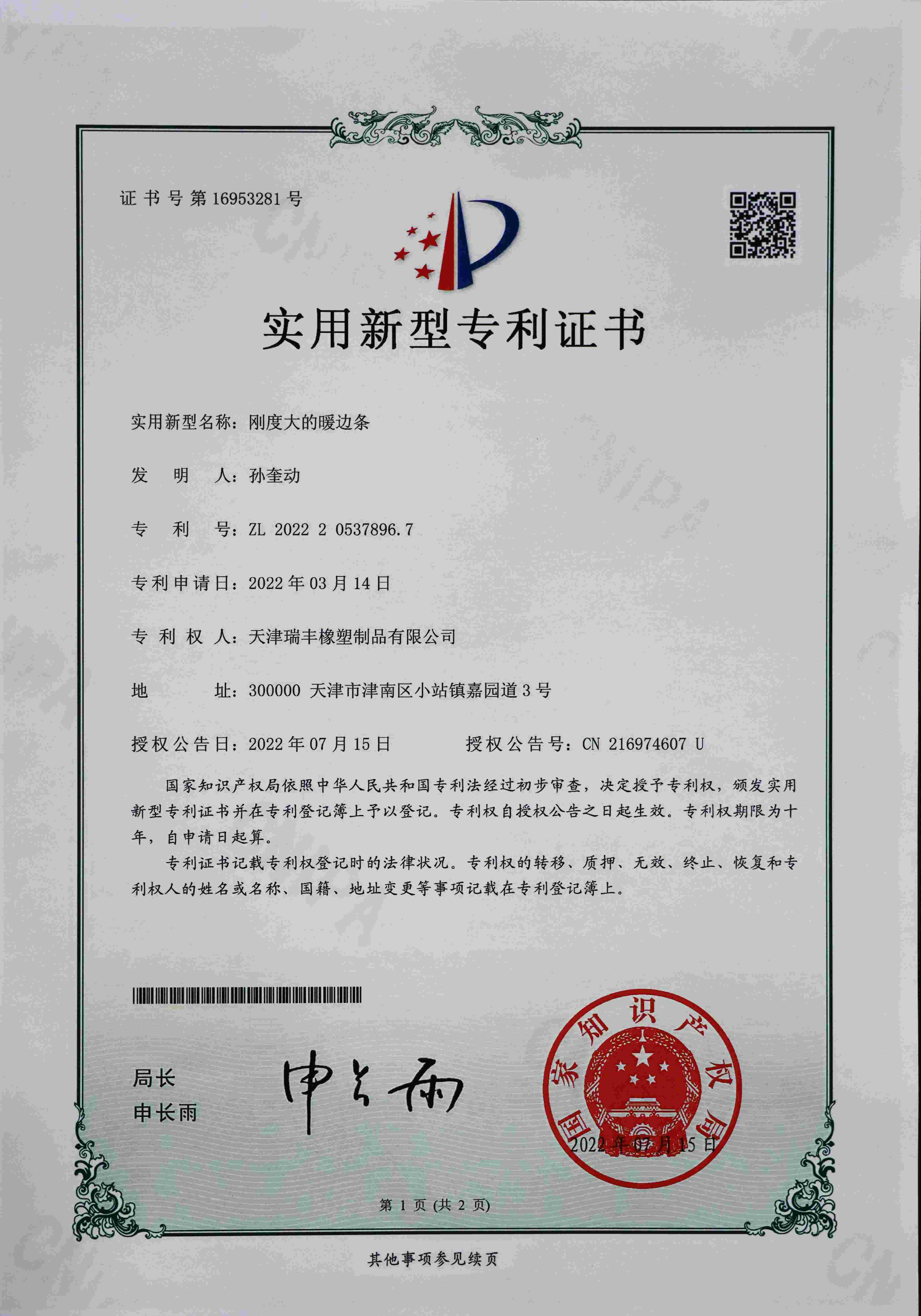

Qualification

In the days to come, our company will be more wholeheartedly working with new and old customers, hand in hand, and common development. Customers are welcome to choose the "Jinruite" brand heat insulation strip series products produced by our company.

FAQ

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!